Vibration sensors became a match-changer in industries that seriously count on equipment and tools. By applying Innovative technologies like these, organizations can achieve unparalleled performance in asset management and maintenance techniques. This site dives deep to the significant function of vibration sensors, their characteristics, And exactly how they’re reworking firms currently.

Table of contents:

comprehension the purpose of Vibration Sensors in Predictive Maintenance

vital options to Look for in Industrial Vibration Sensors

Case reports: prosperous Asset Management with Vibration Monitoring

upcoming developments in Vibration Sensor know-how for Maintenance options

knowing the Role of Vibration Sensors in Predictive Maintenance

Predictive routine maintenance has entered the Highlight as among the simplest procedures for extending machines life and minimizing downtime. Vibration sensors lie at the guts of this system. These sensors constantly observe the vibration levels of machinery, determining anomalies which could signal have on, imbalance, or misalignment before a failure occurs. such as, industrial setups that deploy vibration sensors together with RFID playing cards leverage real-time data to detect likely procedure failures. This enables providers to plan repairs proactively as opposed to reactively addressing breakdowns. businesses for example ZETA IoT have built-in this kind of know-how to provide predictive routine maintenance methods which can be both of those responsible and scalable.

crucial attributes to Look for in Industrial Vibration Sensors

the significance of picking the right vibration sensor can not be overstated. vital features to prioritize incorporate accuracy, longevity, and compatibility with existing systems. Sensors ought to be effective at withstanding severe conditions, earning them ideal for industries which include production and logistics. goods much like the ZETag-C3A from ZETA IoT Mix RFID and vibration-sensing abilities to aid stock and asset administration while becoming Strength-economical. Moreover, authentic-time analytics empowers businesses to make more rapidly plus much more educated servicing conclusions. A center on these attributes assures you’ll get highest benefit out of your investment decision, lowering operational fees eventually.

situation scientific tests: effective Asset Management with Vibration checking

A closer check out serious-earth examples sheds mild to the tangible advantages of making use of vibration sensors. look at a logistics enterprise that integrated vibration monitoring to improve the lifecycle of truck engines. By examining vibration patterns, the corporate discovered use in relocating elements early, greatly lessening breakdown frequency by 35% and saving 1000's every year on emergency repairs. One more situation includes ZETA IoT’s ZETag-C3A, which served industries decrease asset loss fees and boost container turnover with its RFID and predictive routine maintenance capabilities. These illustrations underscore how vibration sensors don’t just strengthen upkeep routines; they safeguard earnings and Make operational resilience.

upcoming Trends in Vibration Sensor technological innovation for routine maintenance answers

Vibration sensor technological innovation is on the brink of thrilling breakthroughs. The combination of IoT, AI, and device Mastering with vibration checking programs will empower much more sturdy predictive algorithms. These enhancements assure bigger accuracy in detecting faults and predicting upkeep requirements. Moreover, as LoRa know-how will become far more prevalent, its seamless connectivity over huge industrial networks will guarantee better yet facts transmission abilities. Innovations like ZETA IoT’s LoRa-enabled sensors pave the best way for long-vary and lower-electricity programs, making them ideal for asset administration in widespread industrial setups. around the next 10 years, we will be expecting vibration sensors to be smarter, far more interconnected, and crucial tools inside of predictive upkeep options.

Vibration sensors are reworking how companies tactic asset administration, integrating State-of-the-art analytics and authentic-time monitoring to scale back read more charges and Increase efficiency. no matter if you’re planning to carry out predictive routine maintenance options or enrich provide chain functions, adopting technologies which include ZETA IoT's ZETag-C3A will help you to stay ahead in an increasingly competitive industrial landscape. examine more details on vibration sensors and also other predictive resources to just take the following big stage in revolutionizing your asset management strategy.

Bradley Pierce Then & Now!

Bradley Pierce Then & Now! Judd Nelson Then & Now!

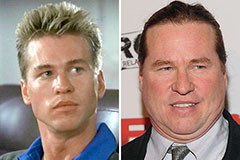

Judd Nelson Then & Now! Val Kilmer Then & Now!

Val Kilmer Then & Now! Christina Ricci Then & Now!

Christina Ricci Then & Now! Pauley Perrette Then & Now!

Pauley Perrette Then & Now!